Vehicles EMC ISO7637-2

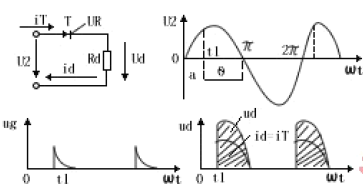

The automotive electrical system is mainly divided into three parts: the generator, the battery, and the automotive electronic system. The generator is responsible for being the main source of power required by the vehicle's electrical appliances during normal operation. When the vehicle's operating environment is complex, the onboard electrical appliances are constantly exposed to the impact of high-voltage pulses, and one source of these high-voltage pulses is the load shedding, which poses a serious safety hazard to the onboard electrical appliances. The so-called "load shedding" means suddenly disconnecting the load of the normal operating automotive alternator, which is called "single load shedding." Disconnecting the load while also disconnecting the battery is called "double load shedding." Due to the high reliability requirements during vehicle operation, a dedicated test standard for automotive electronics has been introduced: ISO 7637-2. Causes of Load Shedding Voltage The generators currently used in automobiles are all three-phase synchronous AC motors. When the load of the generator is suddenly disconnected, the current in the stator winding will suddenly decrease, but the current of the stator winding inductance cannot change abruptly, and a transient pulse voltage will be induced at this time to prevent its decrease; at the same time, the excitation current of the generator is large, and when the load is suddenly disconnected, a transient high voltage will also be generated in the excitation winding. Therefore, the load shedding transient voltage is actually composed of two parts: the transient overvoltage of the stator winding and the transient overvoltage of the excitation winding. Hazards of Load Shedding Voltage The automotive electronic system can be classified into wire harness systems, onboard electrical appliance systems, and controller systems. The wire harness system connects the generator, battery, onboard electrical appliances, and controllers of the vehicle to form a whole. The wire harness system can be understood as the meridians of the vehicle; the onboard electrical appliances are the most contact system with users, such as lamps, air conditioners, wipers, skylights, etc. It is the executive terminal during vehicle use; the onboard controller system is the controller of the vehicle's logic, controlling the conditions for the activation and deactivation of onboard electrical appliances, such as BMS, BCM, PEPS, etc. The transient high voltage (commonly known as load shedding voltage) generated by load shedding will be loaded onto any electrical appliance and controller of the vehicle through the wire harness system. They will withstand the impact of this load shedding voltage. If it is serious, it will cause damage to the onboard electrical appliances and controllers. Factors Affecting Load Shedding VoltageThe most common methods of load shedding are divided into: shedding the battery and shedding the onboard electrical appliance. Many factors affect the size of the load shedding voltage, and the most important factor is the SOC of the battery when load shedding and the engine speed when load shedding. Our company's onboard cameras, onboard displays, onboard warning lights, and other products are all designed with anti-load shedding pulse voltage circuit devices, and we have professional load shedding pulse voltage test equipment.